EURO-4,5 Large Diesel Vehicle Naturally Regeneration DPF Research on Improvement through Improvement of Regeneration

Copyright Ⓒ 2021 KSAE / 191-01

This is an Open-Access article distributed under the terms of the Creative Commons Attribution Non-Commercial License(http://creativecommons.org/licenses/by-nc/3.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium provided the original work is properly cited.

Abstract

The European Union(EU) standard is applied to the emission standards of domestic diesel vehicles, and the emission standards for large-sized diesel vehicles are also introduced and strengthened in stages from Euro 1 to Euro 6, thus reflecting the domestic situation. In large diesel vehicles, mass-produced natural regenerative DPFs often clog DPFs due to regenerative condition failure, resulting in increased ash accumulation, insufficient output, and excessive exhaust emissions. As a result, the inspection failure rate of large diesel vehicles increased, resulting in an increase in unnecessary maintenance costs for consumers, including unexpected DPF cleaning expenses during re-inspection, and social costs for improving the atmospheric environment. Therefore, it is necessary to reflect only the combined regeneration method that can forcibly regenerate vehicles with excessive exhaust emissions among Euro 4 and Euro 5 heavy-duty diesel vehicles, and to expand support for installation costs subject to the installation of PM-NOx reduction devices. If system improvement is implemented as a way to further strengthen the inspection system afterwards, the effect of actively coping with the air environment improvement can be obtained. In conclusion, it can be used as a virtuous cycle tool for social cost benefits, as it can lead to a decrease in medical expenses and a decrease in DPF cleaning expenses due to an increase in human life expectancy.

Keywords:

Air environment improvement convenience, Cost-benefit to improve the regeneration of abatement devices, Analysis of improvement effect of automobile inspection pass rate, Vehicle inspection cost benefit economics analysis, Estimation and quantification of reductions according to exhaust gas improvement scenarios1. Introduction

The standards of the European Union(EU) are applied to the emission standards for the diesel vehicles operating in Korea. The emission standards for large-sized diesel vehicles were introduced in stages from Euro 1 to Euro 6 by reflecting the grace period and domestic conditions based on the European application point of time. These reinforcement measures are actively responding to boosting the reduction effect of particulate matter(PM), as well as the reduction effect of nitrogen oxides(NOx). Nevertheless, the fact remains that high particulate matter concentrations are observed in some areas where large-scale diesel vehicles are driven. This fact points out that it is important not only to strengthen the inspection system for large diesel vehicles, but also to maintain and manage pollutant reduction devices. It also indicates a need to prepare system improvements to actively suppress the emission of particulate matter(PM) and nitrogen oxides(NOx). Such environmental improvement efforts prove the justification for institutional improvement through the analysis of the increase in social cost and the benefits associated with it. In fact, they also play a significant role in the effort to improve the efficiency of the operation of the emission reduction project derived from the deduction of the maintenance plan.

Diesel engines, the main power engines adopted mainly for large-scale diesel vehicles, were once chosen a lot due to their advantages of low fuel efficiency, high engine efficiency, and cost-effectiveness.

However, depending on the degree of post management, nitrogen oxides(NOx) and particulate matter(PM), which are generated due to the nature of combustion, are not 100 % completely purified through the pre-treatment process and the post-treatment process. Some exhaust gases are discharged into the atmosphere, thus causing air pollution and serious damage to human health. In particular, efforts have been insufficient to carry out the inspection and maintenance of the exhaust gas systems, which is required periodically in large diesel vehicles with a large displacement of 3.5 tons or more. Inspection and maintenance efforts have also been insufficient due to factors such as cost burden.

In a pure market economy, vehicle owners make light of air pollution caused by the operation of their vehicles and fail to take responsibility. They do not view the maintenance management of their vehicles as an effort to improve the environment, but perceive it only as a personal expense.

Therefore, it is important to enable consumers to recognize the aspect of redistribution of social costs that will be returned in the future for environmental improvement costs through cost-benefit analysis.

Such efforts can specifically help the vehicle consumers to recognize the need for the “reduction of structural corrosion resulting from the improvement of environment and air quality, for the reduction of medical expenses resulting from the reduction of diseases, etc”.

This study obtained its contents by referring to research on deriving indicators and establishing measurement methodology for the reduction of particulate matter and greenhouse gas in the transportation sector, which is a case study of domestic and overseas emission reduction effect analysis, as well as economic analysis research data of the automobile inspection system and cost-benefit research data for large diesel vehicle inspections. It is emphasized that we need to pay close attention in order to realize how important air environment improvement efforts are for a better future global environment and improve the emission reduction project into a more practical and effective system based on effective maintenance measures.

In addition, the effect of improving the regeneration of diesel particulate filter(DPF), a natural regeneration method of existing diesel vehicles, reduces concerns about the inefficient waste of social costs by consumers and institutions caused by inefficient management. In fact, it also contributes to the reduction of the test failure rate. The re-inspection rate of consumers will also be lowered, thereby generating a virtuous cycle of benefits that will be returned to both institutions and consumers through an effective profit improvement.

It is a good guideline for encouraging the active public response of car consumers to recognize the need for active participation in the maintenance management system of large diesel vehicles for air environment improvement.

What should we do for the atmospheric environment? The priority is to determine how we can contribute through that effort. These efforts enable a cost-benefit analysis to predict the impact of the social cost of system improvement on the future air environment improvement.

If we analyze the feasibility of the method for calculating the amount of reduction that will appear as a result of the reduction of harmful emissions, it will contribute to the estimation and quantification of the amount of reduction of hazardous emissions according to the future smoke emission standard strengthening scenario.

This study conducts a cost-benefit analysis in order to improve the future emission standards for large-scale diesel vehicles. To this end, it applies reasonable reduction measures for social costs incurred for the purpose of improving the air environment to an effective maintenance methodology in order to determine feasibility. Furthermore, this study aims to verify the economic feasibility of institutional improvement by quantifying the total social costs and benefits of the present value and by analyzing the reinforcement scenario of the inspection system to be improved in order to increase social benefits.

2. Social Cost Analysis

Chapter 2 discusses the problems caused by the failure of DPF regeneration in the natural regeneration method of domestic Euro 4 and 5 large-sized diesel vehicles. The social costs incurred for the solution are analyzed. The reason for this is that this study identifies the possible causes of cost increase and derives measures to reduce social costs, which will be used as the basis for cost-benefit analysis.

2.1 Causes of Increase in Diesel Particulate Filter(DPF) Maintenance Cost and the Vicious Cycle

In order to meet the natural DPF regeneration condition, the regeneration temperature must be 600 °C or higher for 10 minutes or longer to oxidize the fine particles.

In addition, an ideal condition for performing DPF regeneration more perfectly is to drive at 1,500~2,500 rpm for 25 minutes or more under the condition of 2nd gear or higher at a speed of 60 km/h or higher as possible. However, this is inevitably an impossible driving pattern considering the current situation of city road driving in Korea.

As a result of the condition failure of DPF regeneration in the natural regeneration method, the DPF is repeatedly clogged. This continuously increases the deposition of ash, which is a metal oxide component generated from the lubricating oil component of the vehicle and the metal component of the engine cylinder liner. Also, the effective volume for soot deposition inside the DPF carrier decreases, thus increasing the differential pressure. This causes various problems, including the reduction of the regeneration cycle and worsening of fuel economy, reduction of output, and oil deterioration. This eventually worsens the DPF status due to the incomplete termination of regeneration.

However, if the DPF is repaired and reusable, the solution can only be achieved by the repair company’s compulsory DPF cleaning. It brings the burden of having to spend several hundred thousand won to several million won or more of DPF repair costs. This leads to consumers falling into the temptation of illegal remodeling or fraudulent inspection, thereby causing the vehicle to continuously suffer from coaggravation by managing it in a more lethal state in the atmospheric environment.

2.2 An Increase in Diesel Particulate Filter(DPF) Maintenance Cost

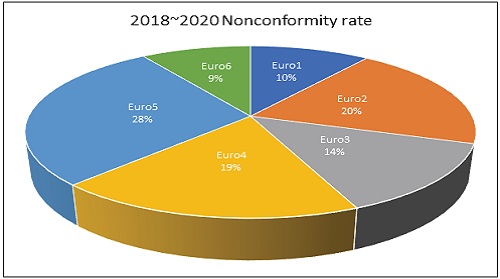

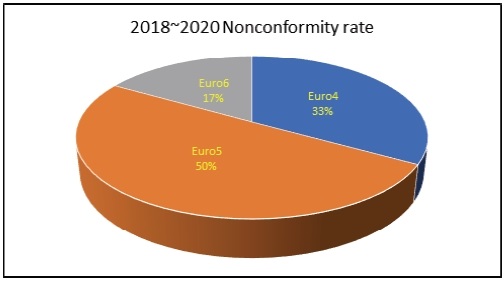

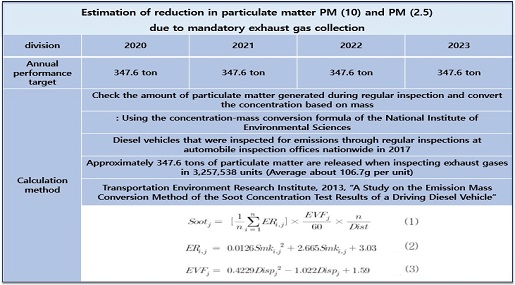

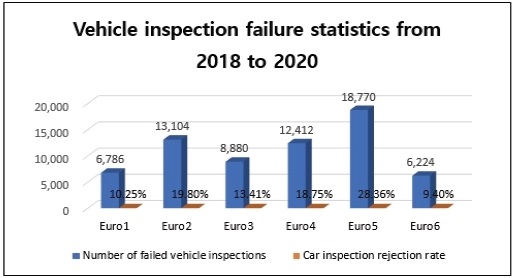

For the analysis of Figs. 1 and 2, the VMIS vehicle registration data of the Ministry of Land, Infrastructure and Transport, and the VIMS inspection result data of the Korea Transportation Safety Authority were obtained, analyzed, and tabulated. As a result of analyzing the obtained data, the total number of nonconforming inspections for Euro 4 and 5 large diesel vehicles was 31,182 from January 2018 to December 2020. As shown in Fig. 1, if we analyze the failure rate from Euro 1 to Euro 6, Euro 5 ranks first with 28 %, followed by Euro 4 with 19 %. In addition, in the range of Euro 4 to Euro 6 analysis shown in Fig. 2, Euro 5 was found to account for the highest failure rate of 50.2 %.

Table 1 shows the DPF maintenance cost of natural regeneration or complex regeneration. Usually, KRW 462,000 (cleaning cost of KRW 450,000 and call monitoring cost of KRW 12,000) is set. If the current DPF cleaning cost is set at KRW 450,000 in a normal maintenance, where most of the maintenance measures are DPF cleaning, Euro 4 and 5 will incur an average annual maintenance cost of KRW 4.677.3 billion over the three-year period.

In addition, Table 2 shows the maintenance cost of the DPF equipped with the PM-NOx simultaneous reduction device. Diesel exhaust fluid cost is included, which increases the cost for consumers even further. Normally, the cost of diesel exhaust fluid is KRW 1.8 million, the cleaning cost is KRW 450,000, and the call monitoring fee is KRW 12,000, so the maintenance cost is KRW 2,262,000.

The PM-NOx reduction device has already been installed from the Euro 6 vehicle mass production stage. Among the 5th-grade-old diesel cars before Euro 3, for vehicles exceeding the emission limit, vehicle scrapping was recommended or the device was installed as part of the mandatory reduction device project.

An important issue raised along with the installation of a reduction device is the preparation of realistic measures for follow-up management.

In particular, it was confirmed that the DPF blockage due to failure to regenerate the naturally regenerated DPF vehicle targeting Euro 4 and 5 accounts for most of the causes of failure of the vehicle exhaust gas inspections. Therefore, it is believed that selecting the complex forced regeneration method rather than the natural regeneration method from the beginning of installation enables a more efficient follow-up management.

As a countermeasure against old diesel vehicles that fail the emission inspection, the natural DPF regeneration installation project among the low-pollution projects should be restrained. Instead, it is persuasive enough to encourage a complex regeneration method that enables forced and manual regeneration. Unnecessary maintenance costs can be prevented by supporting the expanded installation of the PM-NOx simultaneous reduction device. In addition, the measure will serve as a means of preventing the harmful effects of illegal remodeling and fraudulent inspection.

3. Analysis and Quantification of Gas Emission Reductions According to Gas Emission Standard Reinforcement Scenarios

The scenario presented in Chapter 3 for strengthening the emission standards is thought to be possible within the range in which the successful maintenance of the DPF regeneration of domestic large diesel vehicles is normally guaranteed. It is meaningless to estimate and quantify the amount of reduction according to the scenario in a situation where it cannot be maintained normally. Also, the significance will diminish with the illegal remodeling and fraudulent inspection data of vehicles that do not pass inspection.

In addition, the scenario of this study was constructed with reference to the study on deriving indicators and establishing measurement methodologies for the reduction of particulate matter and greenhouse gases in the transportation sector. Social benefits will be quantified through the quantification of reductions.

3.1 Estimation and Quantification of Emission Reductions by Gas Emission Suppression Plan

Reducing the number of vehicles on the road that do not comply with exhaust gas inspection and implementing a zero gas emission policy during vehicle inspection are intuitive ways of suppressing harmful emissions. As such, according to the research results of the Korea Transportation Safety Authority, about 3,962 tons(12.2 % of the government’s particulate matter reduction target) out of 32,360 tons(by 2022), the government’s particulate matter reduction target in the transportation sector, is expected to be reduced by the method of the authority’s promotion strategy. In addition, measures have been taken to strengthen the main culprit of high-concentration particulate matter in Korea. That is, as of March 2018, the government has implemented the 「Enforcement Decree of the Framework Act on Environmental Policy」, which strengthens the environmental standards for ultra particulate matter(PM2.5) with a diameter of 2.5 μm or less, to an average daily average of 35 μg/m3 and an average annual average of 15 μg/m3.

3.2 Minimization of the Road Driving of Noncompliant Vehicles

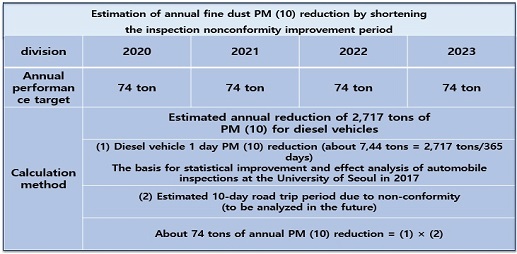

As shown in the analysis in Fig. 3, if a system improvement is implemented that shortens the nonconformity improvement period from the current maximum of 72 days to a maximum of 10 days, it will minimize the vehicle operation time during the nonconformity improvement period. This will minimize the loss to the annual 2,717 tons of particulate matter reduction effect, which is the improvement result of strengthening the inspection system for nonconforming vehicles on the road. In the case of the current maximum operation of 72 days, a reduction effect loss of 532.8 tons occurs. When the period is shortened to 10 days, the reduction effect of 458.8 tons will be recovered so that only 74 tons of fine dust particulate matter(PM10) per year will suffer a loss of the reduction effect.

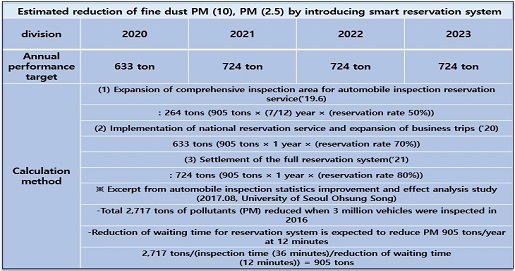

3.3 Implementation of Zero Gas Emission Policy for Vehicle Inspection

As shown in Fig. 4, the emission reduction rate obtained by minimizing the waiting time through the smart reservation system and the emission reduction rate - the reduction effect of particulate matter(PM10) and dust particulate matter(PM2.5) - obtained by requiring inspection sites to collect soot smoke will minimize the inspection waiting time, thus reducing 724 tons per year from 2021. As shown in Fig. 5, the mandatory soot smoke collection facility at the inspection site is expected to enable a reduction rate of 347.6 tons per year.

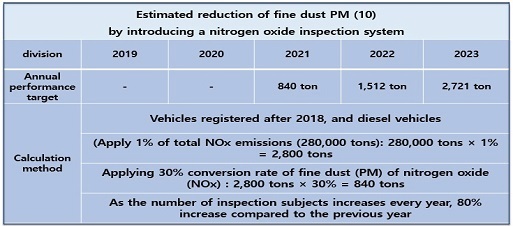

3.4 Analysis of Reduction Rate by the Introduction of Nitrogen Oxide(Nox) Inspection

As shown in Fig. 6, the ultra-fine particulate matter(PM10) reduction through the introduction of the nitrogen oxide inspection system can be expected to be at least 840 tons. This will also suppress the emission of nitrogen oxides, which are harmful substances. Thus, these measures can improve the global atmospheric environment and increase human life expectancy.

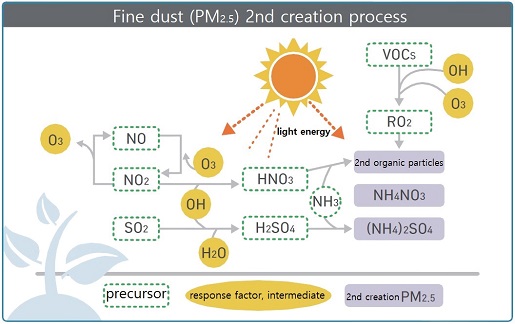

As shown in Fig. 7, we must be vigilant about nitrogen oxides. When nitrogen oxides are released into the atmosphere, they are converted to nitrates and become the ultra-fine dust particulate matter(PM2.5). In the process, when they come in contact with strong sunlight, the nitrogen dioxide reacts with oxygen to form ozone.

Therefore, nitrogen oxide is the first substance to be reduced to control the ultra-fine dust particulate matter (PM2.5) and ozone. Efforts should be made to suppress the formation of nitrogen oxides and volatile organic compounds, which are the causes of ozone generation.

4. Expectation Effect for the Reduction of Vehicle Inspection Failures and Cost Reduction by Improving Diesel Particulate Filter(DPF) Regeneration

Chapter 4 analyzes the expected effect of reducing the number of vehicles failing the inspection, thanks to the improvement of DPF regeneration and the calculation of the cost-benefit synergistic effect obtained through cost reduction.

For the analysis of Figs. 8 and 9, the data obtained from the VMIS vehicle registration data of the Ministry of Land, Infrastructure and Transport and the VIMS inspection result data of the Korea Transportation Safety Authority were obtained, analyzed, and tabulated. Based on the analysis, it is expected that cost reduction through the efforts for maintenance improvement aimed at reducing rejected vehicles will be drawn as a major result in the future economic analysis of cost-benefit.

4.1 Analysis of the Number of Vehicles that Failed the Euro 4 , 5, and 6 Inspection

As shown in Fig. 8, the analysis of the number of vehicles that failed the inspection yielded the following results. For 3 years(2018 to 2020), the number of vehicles that failed the Euro 4 and 5 inspection was 31,182, and the number of those that failed the Euro 6 inspection was 6,224.

Every year, an average of 10,394 vehicles that failed the Euro 4 and 5 emission standards inspection are mass produced. The number of vehicles that failed the Euro 6 inspection stands at an average of 2,075 per year.

Regarding Euro 5, which has the highest failure rate, the number of vehicles that failed the inspection is 18,770 for 3 years, and the annual average is about 6,257.

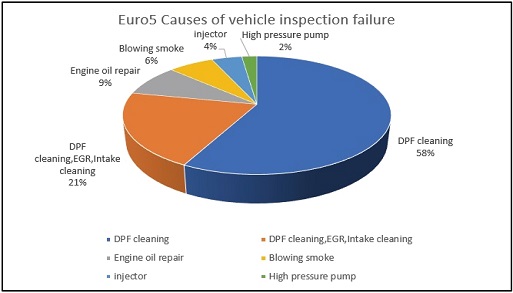

As shown in Fig. 9, the main cause of gas emission test failures was DPF clogging. As a result of maintaining and resolving the problem, 58 % of the vehicles underwent DPF cleaning, and 21 % underwent a set of maintenance including DPF cleaning, intake line cleaning, and EGR cleaning. Most of the maintenance methods were DPF cleaning work.

Even if the DPF cleaning cost is usually calculated only at KRW 450,000, an annual maintenance cost of KRW 1,633 million for 3,629 vehicles(58 %) can be saved.

Thus, DPF regeneration improvement is absolutely necessary. If in the project of attaching a reduction device for vehicles that do not comply with emission inspection, efforts are made to actively encourage the attachment of composite regeneration style. Also, if vehicle owners are properly educated about the importance of maintenance, then the expected effect of environmental improvement and cost reduction will be further enhanced.

4.2 Application of Cost-Benefit Analysis of the Policy to Strengthen Gas Emission Inspection Standards

The cost-benefit obtained from the effect of environmental improvement is closely related to the effort to reduce soot smoke emission. The cost-benefit analysis is calculated as shown in the following formula.

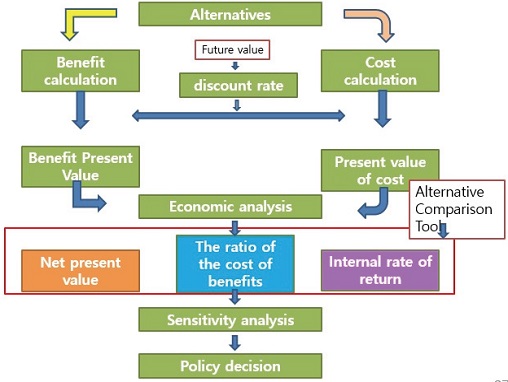

The cost-benefit ratio is calculated as the total social benefit divided by the total cost. A cost-benefit analysis can be carried out in order to examine the utility of how the policy to strengthen the gas emission inspection standards will be effective. The cost-benefit analysis(CBA) or benefit-cost analysis is a method of economic evaluation in this case. It is a technique widely used in many fields, especially in national policy making. It is an analysis method that evaluates whether to implement a project by comparing the benefits and costs generated by the project.

As such, a portion of the future benefits and costs involved in conducting a business is converted into present value. If the ratio is greater than 1 when dividing the value of the total benefit by the total cost, the project is determined as economically feasible. It is mainly used to analyze the feasibility of public investment projects, such as preliminary feasibility studies. Here, the total social benefit is the social cost obtained from the soot smoke emission reduction effect due to the strengthening of the inspection system. The details are explained below. The ratio is calculated by multiplying the total soot smoke emissions by the social cost of soot smoke. The total soot smoke emissions consist of soot emissions reduced through the inspection and maintenance of vehicles that failed the inspection; soot emissions that are reduced by scrapping vehicles or moving them to other areas; and reduced soot emissions obtained by vehicle owners performing prior inspection and maintenance of their vehicles prior to the inspection. The total cost is the total cost incurred for performing the inspection.

As such, the total cost is divided into direct cost and indirect cost. Direct cost consists of the facility investment cost for the installation of inspection facilities and equipment, and the labor cost of inspection personnel. Indirect cost consists of the vehicle owners’ fuel costs incurred by moving the vehicle to undergo an inspection; loss of labor cost of the vehicle owner caused during the time required for inspection; social loss cost caused by soot emitted when nonconforming inspection vehicles are moved; pre-inspection and maintenance cost of vehicles subject to inspection; and maintenance cost of nonconforming vehicles. This study gave an opportunity to take a closer look at the effects of harmful emissions of large diesel vehicles on the atmospheric environment. It also served as an alert to the fact that there are social costs that we do not have to incur.

Although it is natural that if there are expenses, there will be benefits therefrom, the benefit of environmental improvement, socially returned and obtained, was only considered as a loss viewed from one side. In the end, the cost and social benefits both increased, which is revealed as an incremental effect of improvement.

The cost-benefit is obtained from the cost calculation resulting from the right alternative search and efficient environmental improvement. It is returned as the net present value of the environment in which we live, which has economic value.

A negative roadmap of wrong alternatives(calculation of illegal modification costs, taking of fraudulent inspection fees, etc.) leads to environmental destruction. This, in turn, leads to the increase in the cost of treatment for diseases due to the decrease in human life expectancy, and to waste of maintenance costs. Thus, there is an increase in costs that are not expected to generate net present value and correct internal revenue, thus resulting in a reduction in cost-benefit costs.

5. Conclusion

- 1) In order to solve the problem of high particulate matter concentrations in large cities, it is important to improve the inspection system for large diesel vehicles in operation. The management of after-sales maintenance of emission pollutant reduction devices is also very important. This proves that harmful exhaust gases emitted from diesel vehicles have a very large impact on air pollution.

- 2) The damage caused by DPF regeneration failure has an adverse effect on the exhaust gas emission reduction performance. It increases the accumulation of ash and lack of output due to the clogging, thus reducing the effective volume for the deposition of soot inside the DPF carrier. This creates a big problem in the maintenance system.

- 3) The 『5030 Systemdoes』 not impede DPF regeneration. Instead, the realistic driving condition of vehicles repeating ‘stop and go’ in the city center due to traffic jams is the cause of preventing the meeting of DPF regeneration conditions. Therefore, it is not a problem of the 『5030 System』.

- 4) If DPF maintenance and management is performed well through the method improvement involving forced regeneration, there will be no clogging of the DPF. As such, the cost of cleaning the DPF will not be wasted.The performance of the reduction device can also be maximized so the effect of ancillary environmental improvement can be obtained.

- 5) The effect of the reduction rate of the annual fine dust particulate matter(PM10) can be analyzed by reducing the number of vehicles on the road that fail emission gas inspections. In addition, a total of 3,069 tons of fine dust particulate matter(PM10) and ultra-fine dust particulate matter(PM2.5) can be reduced by 2023 through the improvement of inspection systems such as the smart reservation system.

- 6) A total reduction of 1,388 tons could be expected for fine dust particulate matter(PM10) and ultra-fine dust particulate matter(PM2.5) through the mandatory installation of soot collection facilities at automobile inspection stations.

- 7) The formation of nitrogen oxide, which is the main cause of the rise in ultra-fine dust and ozone, should be suppressed through the introduction of the nitrogen oxide inspection system. Thus, the effect of reducing at least 840 tons of fine dust particulate matter(PM10) per year is expected to be generated.

- 8) For the protection of the environment, efforts should be made not to spare the investment of social costs. Yet, a heavy punitive system should be applied to the cases of misuse of the system by vehicle owners for expedient vehicle modification, etc., so that social costs can be reduced. It is necessary to increase the cost by investing in social costs. Benefits increase with the strengthening of the inspection system, despite social cost investment being made. However, if expedient illegal remodeling is abused, the punitive system should be strengthened in order to improve the quality of enlightenment.

- 9) Even if the benefits and costs increase together due to the strengthening of soot emission standards and the introduction of nitrogen oxide inspection standards, we can analyze the economic feasibility through the present value of benefits and present values of costs in order to calculate the net present value, benefit-cost ratio, and internal rate of return. Such measures can be used as alternative comparison tools, and they can be very useful when making policy decisions.

- 10) If a more detailed research on cost-benefit analysis is conducted in the future, various discount rates can be assumed based on future economic conditions or business prospects. This makes it possible to conduct sensitivity analysis in order to find out how much business feasibility changes under various discount rates and to offer more accurate suggestions for system improvement. This will sufficiently prove the justification of the improvement effect of the system improvement.

In conclusion, the cause of the cost increase should be analyzed first in order to derive the feasibility of public investment projects, such as preliminary feasibility studies, through a cost-benefit analysis. It should be noted that the cause of the cost increase can be resolved even with effective maintenance measures. It is also possible to prevent an increase in social costs that are wasted without necessity.

In addition, this study has great significance since the increase in social benefits obtained from the inspection system reinforcement scenario plays a central role in improving the cost-benefit.

Acknowledgments

This research was conducted for the Ministry of Environment's project of 『Euro-5, 6 large-sized diesel car emission standard improvement (2020 - 2021)』 with the support of 2021 Joongbu University grant.

References

- Analysis of Data from the Ministry of Land, Infrastructure and Transport VMIS Vehicle Registration Data and the Korea Transportation Safety Authority VIMS Inspection Result Data, 2020.

- Korea Transportation Safety Authority, Fine Dust and Greenhouse Gas in the Transportation Field A Study on the Derivation of Indicators and Establishment of Measurement Methodology for the Reduction of Fine Dust and Greenhouse Gas in the Transportation Field, http://www.alio.go.kr/informationResearchView.do?seq=2663307&url=&s_text=&s_flag=&audit_code=&pageNo=1, , 2019.

- Korea Automobile Environment Association, Low Pollution Business, DPF(Diesel Particulate Filter) Attachment, Maintenance, 2020.

- G. S. Kim, H. S. Lee, G. S. Han and S. Y. Ha, “Cost-benefit Analysis through Reinforcement of Exhaust Emission Standards and Introduction of Nitrogen Oxide Inspection Standards,” KSAE Fall Conference Proceedings, p.1270, 2020.

- Ministry of Environment, Brochure, What on Earth is Fine Dust?, http://me.go.kr/home/web/board/read.do?menuId=10181&orgCd=&boardId=627350&boardMasterId=54, , 2016.

- Cost-benefit Analysis Procedure, https://m.blog.naver.com/PostView.nhn?blogId=jng02&logNo=221580980886&proxyReferer=https:%2F%2Fwww.google.com%2F, , 2019.

- National Institute of Environmental, A Pilot Study of Load Inspection for Large Vehicles by the Korea Transportation Safety Authority, A Study on the Application of Load Inspection for Large Diesel Vehicles, 2005.

- J. Park, D. Kim, J. Bae and S. Kang, “Economic Analysis on Vehicle Inspection(PTI) Scheme,” KSAE Fall Conference Proceedings, p.1377, 2017.